Parts and Accessories

Request Quote

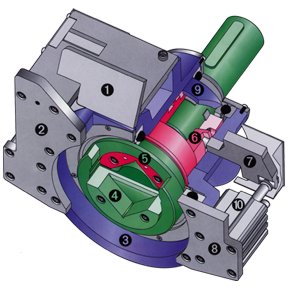

At Boschert, we listen to our customers. You have been telling us what you need in the work place and we have the solution! You need faster turn around time for the operator, less people required to load your Safety Chucks, and increased safety in handling rolls. The A Series offers double redundance safety. It has two back ups to protect the operator. Your Safety Chucks need the capacity, flexibility, and ingenuity to safely carry your operations into the next century. Boschert has the solution!

We started this series with the heavy duty Safety Chucks. Before, integrated pneumatic opening and closing was for light to medium rolls. It did not exist for heavier rolls. Available at this time are the 30-40, 40-50 and the 50-80 size Safety Chucks. They are identified respectively as the A 40, A 50, and A 80.

| Technical data | A 40 | A 50 |

|

|---|---|---|---|

| max. beamweight | 1600 kg | 2800 kg |

|

| max. torque | 350 Nm | 1100 Nm |

|

| max. square bar size | 40 mm | 50 mm |

|

| concentricity | 0.1 mm | 0,1 mm |

|

| air pressure | 5 bar | 5 bar |

|

| max. drive shaft diameter | 40 mm | 55 mm |

|

Hours of Operation: Monday - Friday 9-5 CST

Call: 800-479-0010

Copyright © 2024 Boschert LLC, All Rights Reserved

Web Services: Dogwood Productions, Inc.